Preventing Spray Drift

Dicamba has been in the headlines frequently due to the large-scale incidents of drift damage from illegal or improper application of the chemical in farming operations. The on-site weather at time of application has a significant impact on the risk of drift and should be incorporated into planning spray activities to avoid the potential risk and costly waste of spray drift.

The Key Weather Measurements that Matter When it Comes to Drift Management

"Applicators and farmers put themselves and their businesses at risk every time they spray a field without documenting the wind speed. There is a lot more litigation these days, so not protecting yourself is kind of foolish."

- Bob Beck, Agronomist

Winfield Solutions

Spray drift can cause damage to other crops, plants, animals or equipment on property; escape into the environment causing harm; and result in legal and financial responsibility for off-property drift damage. It can also adversely affect the health of the people doing the spraying. If you are not actively monitoring the spray conditions, following recommended label guidelines, and documenting your actions, you could be opening yourself up to a host of unnecessary trouble and financial loss.

Weather is the Most Important Consideration in Preventing Spray Drift

"Wind speed and direction, temperature, relative humidity, and atmospheric stability all affect spray drift. Wind Speed, however, is usually the most critical meteorological condition. The greater the wind speed, the farther off-target small droplets will be carried."

- Vern Hofman and Elton Solseng

Agricultural and Biosystems Engineering NDSU Extension Service, North Dakota State University of Agriculture and Applied Science, and U.S. Department of Agriculture

Spray drift from the site of application into off-target areas is a violation of most state laws regarding pesticide and herbicide regulations. Applicators are required to follow all product label directions and precautions to reduce the potential of drift and the potentially dangerous consequences.

Current on-site and forecast weather data is essential to planning spraying application times. However, during the actual application, what matters most is knowing the real-time weather on that day and at the specific location where you are spraying. Product labels are beginning to include more information regarding acceptable weather conditions for safe spraying.

Two Types of Spray Drift

- Particle drift is the movement of small spray droplets through the air - usually carried on the wind.

- Vapor drift results from evaporation of the liquid spray into a gas or vapor during hot and dry conditions, which then travels into the environment.

Key Measurements for Effective Spray Drift Management

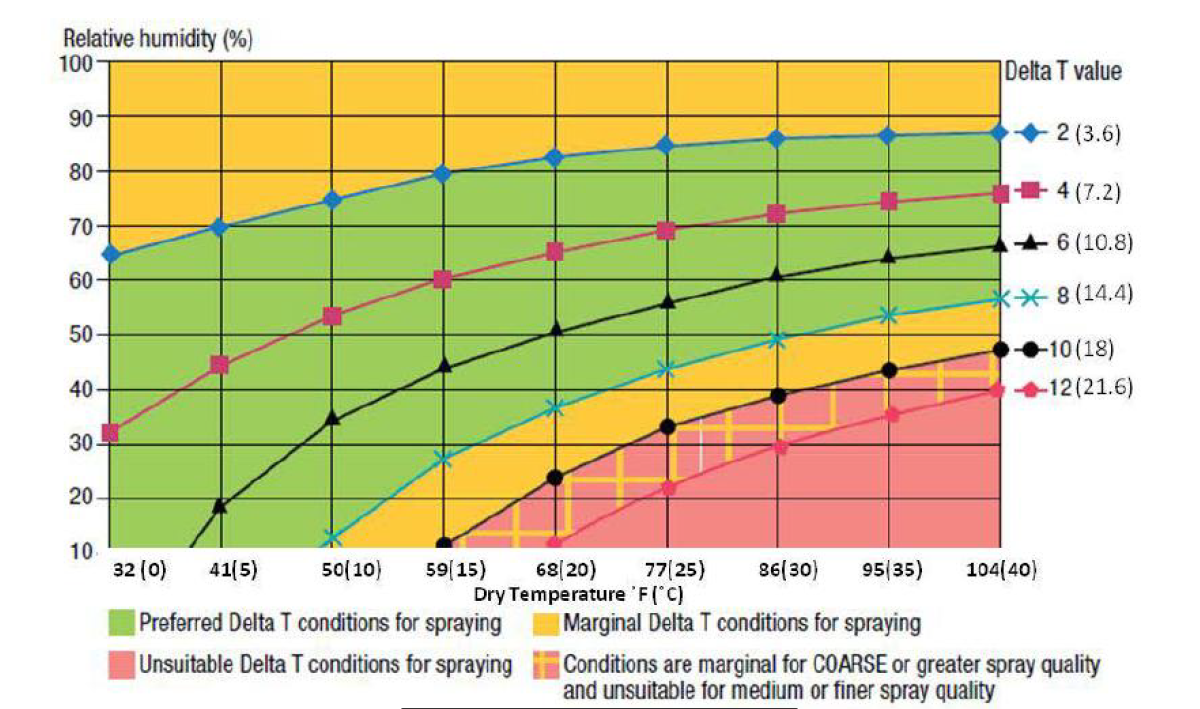

Delta T

Delta T is the difference between the wet bulb temperature and the dry bulb temperature measured in degrees Celsius. Delta T is a useful shorthand for assessing the risk of evaporation and resulting vapor drift. Delta T should ideally be between 2 and 8 when applying sprays, and not greater than 10. High Delta T conditions result in high evaporation rates and poor droplet survival - causing vapor drift and costly waste of the applied chemicals. Low Delta T values (below 2) encourage droplet survival, which can increase the risk of spray drift.

Temperature and Humidity

Separate from Delta T, actual temperature and humidity should also be checked and recorded. Hot temperatures should be avoided if possible.

"High air temperature and low relative humidity go hand-in-hand in creating a worst-case scenario for pesticide drift. Use special caution when relative humidity is below 50 percent and when temperatures are high. Drift is more likely during the hottest part of the day. Hot, dry conditions reduce droplet size through evaporation and thereby increase drift potential. Under these conditions, spray droplets can evaporate very fast and become more susceptible to wind forces. Air temperature can also influence atmospheric stablility and off-target movement of spray droplets."

- F.M. Fishell and J.A. Ferrell

University of Florida, IFAS Extension

Wind Speed

Instinctively, all applicators know that high wind speeds increase the likelihood of particle drift. But "dead calm wind" conditions are also to be avoided.

"Wind Speed is the most important weather factor influencing drift; but unfortunately applicators have no control of it. High wind speeds will move droplets downwind and deposit them off target. On the other hand, dead calm conditions are never recommended because the likelihood of temperature inversion. Drift potential is lowest at wind speeds between 3 and 10 miles per hour - that is, a gentle but steady breeze, blowing in a safe direction away from sensitive areas."

- F.M. Fishell and J.A. Ferrell

University of Florida, IFAS Extension

Wind Direction

Wind direction indicates where off-target spray droplets can be deposited. Many chemicals require the use of a downwind spray buffer to protect sensitive areas and crops.

Applicators and growers should take wind speed and wind direction measurements at spray boom height. In cases of litigation, recording the wind direction in addition to other environmental conditions can help show that spraying did not occur when winds were in the directions of susceptible crops or health-sensitive areas like schools or housing.

Kestrel Environmental Meters for Agriculture

"Pesticides should not be applied when the wind is blowing toward a nearby susceptible crop or a crop in a vulnerable stage of growth. If these conditions do not exist, consider another method of control or time of application."

- Paul E. Sumner

Extension Engineer

Cooperative Extension Service, The University of Georgia College of Agricultural and Environmental Sciences

The Kestrel Agriculture Line of environmental monitoring meters and loggers comprises four models dedicated to the needs of the agricultural professional. The instruments provide a range of environmental and weather measurements and guidance models that help make decisions relating to:

- Safe spraying

- Livestock heat stress avoidance

- Effective ventilation

- Optimum planting and harvesting conditions

- Fire danger avoidance

- Frost management

- Mold and mildew avoidance

- Grain and hay storage

- Aerial equipment safety

...and more!

Pocket sized, rugged, waterproof, affordable, easy-to-use and equipped with on-unit data logging and wireless data retrieval for monitoring and reporting*, Kestrel Agriculture Meters are your trusted weather guides for every farming and ranching need.

Learn more about the Kestrel Agriculture Line.

*Model dependent